|

CONTROL WORKS, INC. "Working With People To Apply Technology" "Offering Affordable Control Systems That Simply Works" Thank You For Allowing Us To Be At Your Service! Serving The Chemical, Oil & Gas Industry |

|||

|

|

||

|

|

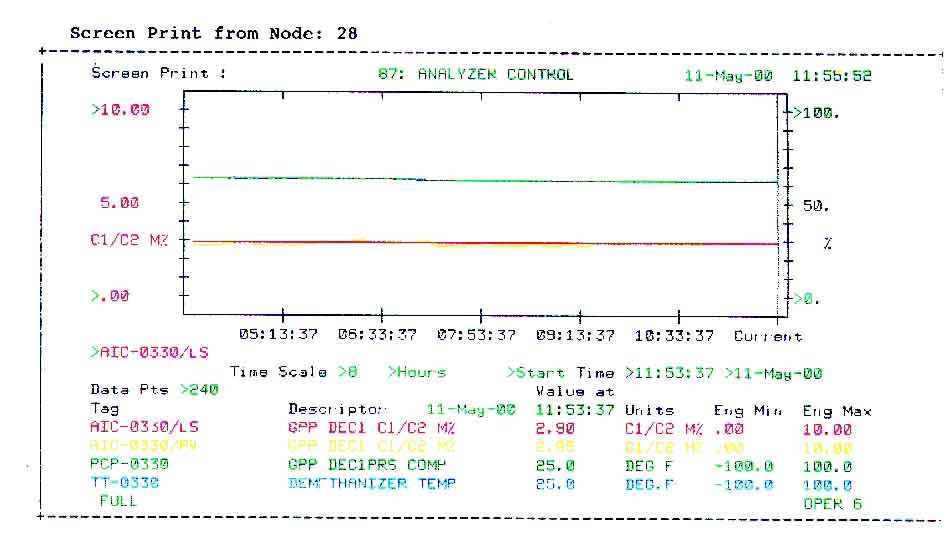

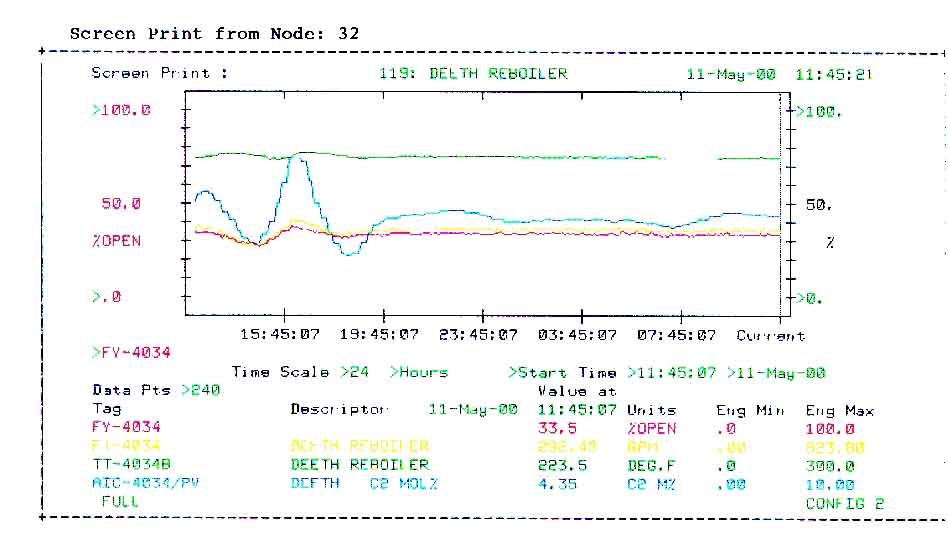

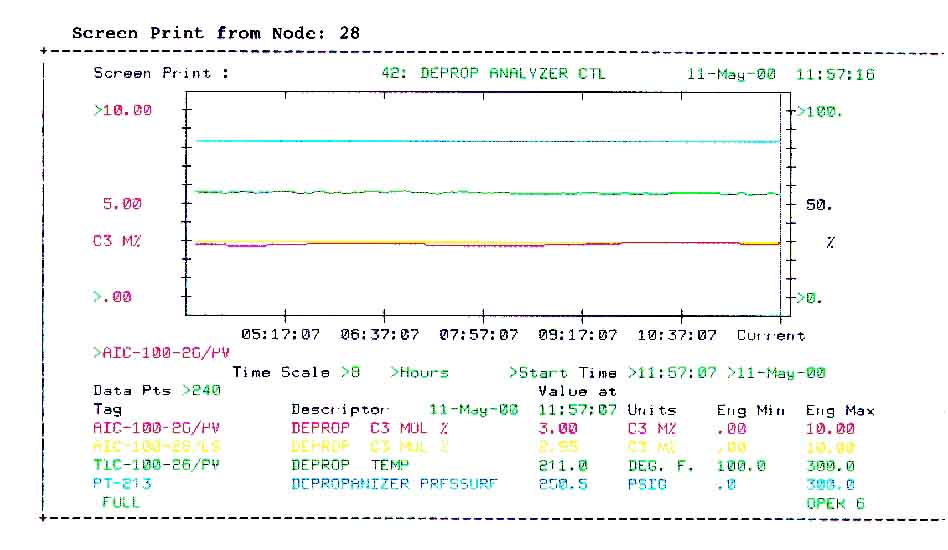

On-line Analyzer Control: Control Works, Inc. engineers have experience on sound technology in on-line analyzer control to control the actual analysis specification of your process. For example, for a demethanizer we can control the actual Bottoms C1/C2 Mole % or the C1 Mole %; For a deethanizer we can control the Bottoms C2 Mole % (See actual DCS printouts below). The control strategies use actual data from the analyzers and a pressure compensated temperature technique. This control strategy can be implemented in a PLC or DCS system and can be applied for other process units. Control Works, Inc. can program the computers, data communications and configure the control system to control your process to actual contractual specifications, thus optimizing your process and increasing your bottom line. Many companies spend many thousands of dollars in analyzers but use them only as an off-line reference to adjust process variables. Other companies spend literally millions in inferred on-line simulators adding more computers, communication gateways, and many more complex unnecessary "gadgets" to control their plants, only to find out that in the long term their so called "advanced" control strategies do not stay on-line.

Control Works, Inc. Demethanizer On-Line Analyzer Controls ACTUAL DCS Trend Printout These Controls Were Implemented Years Ago And They Are Actually Working Today Do Not Let People Just Talk You Around The Bush, Ask Them To SHOW YOU THE RESULTS Control Works, Inc. On-Line Analyzer Control Package Is Simple To Implement And It Simply WORKS!

Control Works, Inc. Deethanizer Before and After On-Line Analyzer Controls Were Turned On This Is An ACTUAL DCS Trend Printout, Not Just Talk

Control Works, Inc. Depropinizer On-Line Analyzer Controls Imagine Your Fractionation Train Products' Specifications On Setpoint And As Steady As These, It Is Like Money In Your Pocket This Is An ACTUAL DCS Trend Printout, Not Just Talk

Control Works, Inc. can put your analyzer to optimum use by transferring your analyzer data to the process control system and automating the control of your plant based on each analyzer result. This way we can adjust the proper manipulated variables to drive process specifications closer to contract limits, therefore maximizing your most valuable products. Best of all, we can do on-line analyzer control in the DCS without "gadgets" and without expensive equipment and other computers, in the same way we can do flow control! Furthermore, since we configure all blocks in the DCS, the on-line analyzer control strategies look and work the same as many other control blocks, giving the plant operator an easy feeling with very little training. Call us at Control Works, Inc. to discuss on-line analyzer controls that stay on-line. |

||

|